This approach is carried out in a scheduled manner to prevent failures and extend the lifespan of the equipment. It involves regular inspections and component replacements based on established timelines. This can include sensor cleaning, checking electrical connections, and calibrating instruments. Preventive maintenance is essential to avoid field failures and ensure success in the measurement campaign.

Maintenance service for the communication cables of oceanographic equipment, including the assembly of new connectors and safety devices.

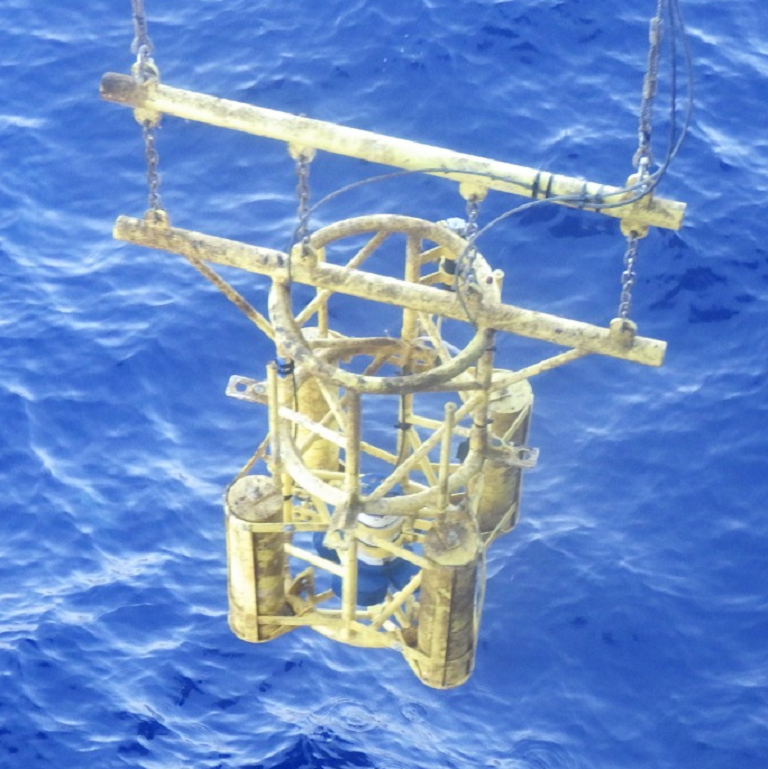

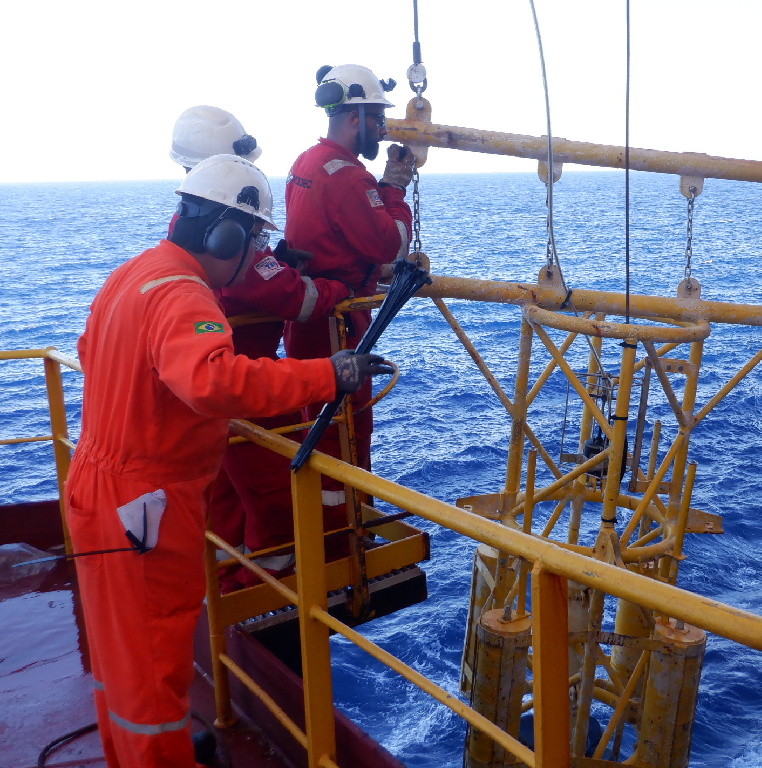

Commissioning service for oceanographic equipment according to the assembly standards required by the equipment manufacturers (Teledyne, FSI, 4H JENA, and Inertial Labs).

In situ calibration service for meteorological equipment (anemometer, barometer, thermo-hygrometer) and motion sensors (MRU) for helidecks.